The pipes, the pipes are calling: Orange man services organs throughout New England, beyond

| Published: 05-09-2025 11:58 AM |

Stefan Maier decided to pull out all the stops in 1993.

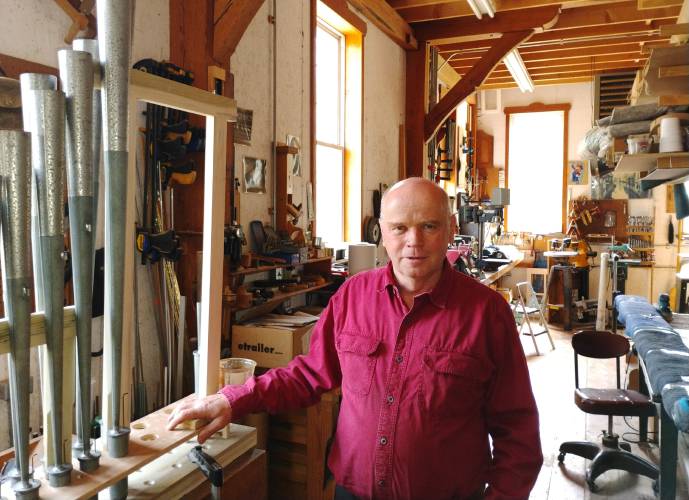

That’s when he became a business owner and started Stefan Maier Tracker Organs, capitalizing on his training and experience, to bring to the North Quabbin region a skill centuries in the making.

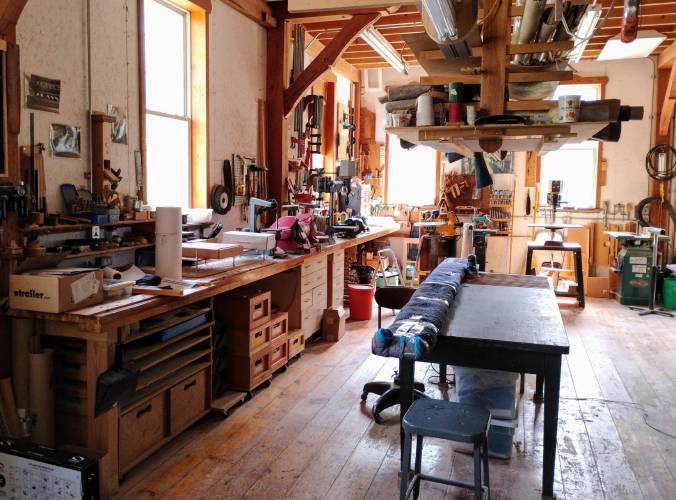

“We’re basically a servicing business. We do tuning and maintenance. When things break, we fix them. That’s our main thing,” Maier said. “A rebuilding job takes us six to 12 months. There’s designing and building ... you know?”

Maier operates a workshop out of his home on Chestnut Hill Road, across the street from Seeds of Solidarity Farm, but often works on pipe organs on location. He has clients ranging from The First Church of Deerfield to Old North Church in Boston to Christ Church Anglican Cathedral in Nassau, Bahamas. His current project is moving a church organ in New Britain, Connecticut.

“The task that we have is to disassemble it and to reassemble it in a new location. It probably weighs around 15,000 pounds. So it’s not like a piano that you pick up and put it in another place,” Maier said. “Usually, an organ doesn’t get moved.”

Maier mentioned the organ, which consists of 1,700 pipes, is 22 feet tall, 16 feet wide, and 5 feet deep. It was made in Germany and installed in the church around 1987. Maier explained the pipes visible on the exterior of the organ case are known as facade pipes. Behind them are various other pipes, including wooden and conical pipes of various shapes and sizes. A tracker organ is one where the keys are mechanically linked to the valves that control the air flow into the pipes. The knob or tab controlling the flow of air to a specific set of pipes, which each produce a unique sound, is called a stop.

“It’s fun if you can work for yourself — you are your own boss. You have your responsibilities and you’re never off the job, really, but at the same time what I enjoy about this work is it’s creative and it presents you with new challenges and you have to come up with solutions every time,” Maier said. “I just enjoy the fact that it never gets boring. There’s always new challenges, new problems to solve. And, my crew, these guys are really good. I’ve got four people working on this job. And they’re just like that, also. They just like to figure things out and so on.”

Maier, 64, did not grew up in a musical family but rather was fascinated by an organ’s mechanics and the various disciplines — woodworking, metalworking, soldering, leatherworking, engineering, computer-aided design — needed to maintain the instrument. He was trained as a pipe organ builder in his home country of Germany after a childhood enthralled by the tutelage of his father, an engineer.

Article continues after...

Yesterday's Most Read Articles

My Turn: Housing referendum — How much more subsidized housing can Greenfield afford?

My Turn: Housing referendum — How much more subsidized housing can Greenfield afford?

New owners at Shelburne’s Kenburn Orchards look to maintain historic property’s heritage

New owners at Shelburne’s Kenburn Orchards look to maintain historic property’s heritage

Small fire threatens fifth-wheel trailer in Heath

Small fire threatens fifth-wheel trailer in Heath

Orange man, 35, dies in crash

Orange man, 35, dies in crash

Cleary Jewelers issued order to vacate Greenfield store by Aug. 23

Cleary Jewelers issued order to vacate Greenfield store by Aug. 23

Greenfield’s Camelot Cat Cafe opening Friday

Greenfield’s Camelot Cat Cafe opening Friday

After finishing his basic education at 19, Maier opted for 21 months of community service as a conscientious objector instead of fulfilling the 18 months of Germany’s then-mandated military service. This took him to Uberlingen, where he resided at a large Catholic church on Lake Constance and worked as an assistant to the priest, maintaining the church, running errands and serving the congregation. Near the end of his service period, the priest asked Maier pick up a display cabinet a member of the congregation had built for the church. Maier arrived at an organ shop and saw a nearly completed, newly-built tracker organ.

“What intrigued me about the organ work is it’s really a large collection of different skills that come together,” he said. “And I realized these guys are real artists.”

He immediately asked about an apprenticeship position but the shop was booked with apprentices for the following several years. So he instead began his career in Bavaria in 1982, receiving his basic training in mechanical action organs. The following year he began working with the Swiss organ builder Eddy Ottes, concentrating tonal finishing, scaling and tuning.

Maier then worked for master organ builder John Brombaugh, in Eugene, Oregon, from 1987 to 1990, when he moved to the south of France to work with Manufacture Provencale D’Orgues. Eventually, some friends visited and encouraged him to start a business in the United States.

“I was young and I was thinking, ‘All right, let’s go for it,’” he said. “So I brought my wife and my kids and my $2,000 and came over here and I started my own business.”

Maier moved to Orange because his then-wife was American and had family in New England. He said friends in Boston and Athol sent a lot of customers his way to get him started.

“With the help of those two people I managed to get this thing off the ground. And today we have lots of work and inquiries,” he said. “It turns out that Orange was not a bad choice. It has a downside [that] a lot of my work was in Boston and Worcester,” he said. “But, at the same time, out here our overhead costs are pretty low.”

Also, he uses solar panels to make his own energy.

“It seems like a dependable, inexhaustible resource,” he said.

In 2012, Maier designed and built a 6-kilowatt mounted photovoltaic system to offset some of his property’s electricity needs. A 7-kilowatt PV system was installed on top of the organ shop three years later.

Reach Domenic Poli at dpoli@recorder.com or 413-930-4120.

Speaking of Nature: Of dragonflies and damselflies: A closer look at their mating habits

Speaking of Nature: Of dragonflies and damselflies: A closer look at their mating habits Local fruit salad just got even better: Try adding a hint of San Antonio spice

Local fruit salad just got even better: Try adding a hint of San Antonio spice Tales from the top: In new book, Heath native Sarah Hartshorne reflects on not becoming America’s Next Top Model

Tales from the top: In new book, Heath native Sarah Hartshorne reflects on not becoming America’s Next Top Model 20 hours to celebrate 20 years: Valley Free Radio host to broadcast for nearly a day, Aug. 7

20 hours to celebrate 20 years: Valley Free Radio host to broadcast for nearly a day, Aug. 7